Hikrobot’s Machine Vision Solutions Enable and Empower Electronics Manufacturing Sector

Hikrobot’s Machine Vision solutions are revolutionizing the electronics manufacturing sector by providing advanced technologies that enhance quality control, efficiency, and productivity. Hikrobot is empowering the electronics manufacturing sector by offering cutting edge technologies and solutions that are adding immense value.

Key Solutions and Benefits

Quality Inspection: Hikrobot’s machine vision systems detect defects, flaws, and deviations from specifications with remarkable precision, ensuring high-quality products.

Object Recognition and Sorting: Advanced algorithms and machine learning capabilities enable efficient sorting and classification of components.

Barcode and QR Code Reading: Hikrobot’s vision cameras provide rapid and accurate data capture, enhancing inventory management and logistics.

Automated Guided Vehicles (AGVs): Vision cameras guide AGVs, improving material handling, transportation, and warehouse operations.

Predictive Analytics: AI-driven analytics enable proactive maintenance, reducing downtime and increasing Overall Equipment Effectiveness (OEE).

Hikrobot’s Product Offerings

Smart Cameras: Equipped with advanced image processing algorithms and versatile tools for pattern matching, color detection, and object counting.

Area Scan Cameras: Provide high-definition imaging for real-time streaming and portability.

3D Cameras: Offer micrometer-level precision for non-contact inspection in electronics manufacturing.

Smart Code Readers: AI-powered readers for efficient barcode scanning and data capture.

By leveraging these solutions, electronics manufacturers can improve efficiency, reduce waste, and enhance overall productivity.

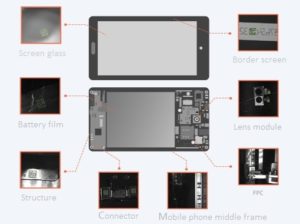

The fast growing electronics manufacturing sector in India needs machine vision solutions at every step. It is one of the largest field of machine vision application. Machine vision application can almost be seen in every link of the electronics manufacturing industry chain, from micro components such as imaging modules and USB connectors, to large mobile phone frame, motherboard of PC and other devices. These include industry applications such as the processing and assembly of electronics components.

Positioning Guidance

Obtain the position information of the measured object through machine vision technology, and guide the robot to carry out a series of operations.

Based on image calibration, target detection, size search and other algorithmic technologies, the main role of robot guidance related applications is to accurately obtain the coordinate position and angle of the object (object to be grasped) and target object (object to be assembled), and convert the image coordinate into the robot coordinate that can be recognized by the robot, and guide the robot to locate and assemble.

Code System Identification

The technology of electronic industry product is complex, in some links of the industry chain, the product identity ID information should be identified.

Demand for electronic devices such as smartphones and tablets has surged. With the increasing number of parts and the rapid development of miniaturization of products, manufacturers are also committed to pursuing high-quality traceability management. In view of the miniaturization of electronic parts, in many cases, the traditional contact printing processing method has been changed to the non-contact high-precision laser printing and processing. Therefore, the requirements for trace printing with fineness, high quality and low damage are increasing day by day.

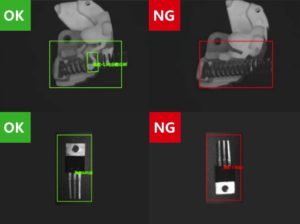

Defect Detection

Detect the scratch, damage, spot, color difference and other defects on the surface of electronic products.

In the process of manufacturing products in the electronic industry, defects can’t be avoided, and the requirements of production enterprises for product quality are keeping raise. Therefore, defect detection is a very important application in the industry. Machine vision has the ability of high precision and high speed detection, which can realize the detection of various defects, including scratch, damage, spot, colour difference, etc.

CNC Mobile Phone Hole Positioning Processing: positioning guidance, CNC, calibration, machining operation

Realize the high-precision search and positioning of the fixed shape hole of the workpiece to be processed, and then carry out machining operation.

The Alignment of FPC and ACF Glue: Alignment fitting, visual positioning, recognition; detection

The FPC and ACF glue are automatically identified and aligned according to the alignment mark. Only the alignment adjustment is needed for FPC each time, and the position of ACF glue is fixed.

Barcode Recognition of Mobile Phone Module: Mobile phone module, QR code recognition, DM, post Scan and read the code of a variety of mobile phone modules without fixed features.

Hikrobot offers bespoke machine vision solutions that are integral to the electronics manufacturing process.